2022/07/05

628

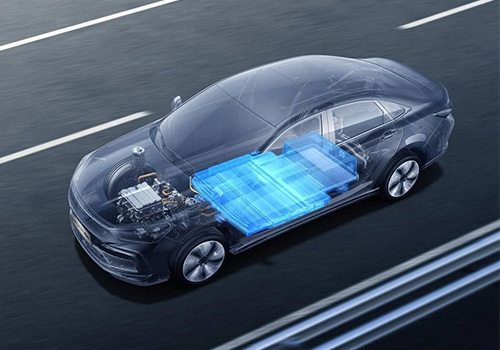

At present, China has become the world's largest new energy vehicle market with the highest growth rate. Due to the explosive growth of new energy vehicle sales, power batteries, which are the core of energy vehicles, have also seen explosive expansion, which in turn has contributed to the rapid development of the entire industry chain of new energy power batteries. With the advantages of high specific energy, better energy storage efficiency and long service life, lithium-ion batteries have gradually occupied the main market share of electric vehicle batteries in recent years.

New energy lithium batteries are mainly composed of 4 parts, namely anode materials, cathode materials, electrolyte and battery separators. Lately, there has been a huge sales increasing of these 4 components, which directly triggered a large demand for industrial gases from various manufacturers. The production of cathode, anode materials and electrolyte requires applying oxygen, nitrogen and other industrial gases as oxidizing gas or protective gas for the production equipment. Through in-depth researches, some lithium manufacturers found that using oxygen as the protective gas is more effective than nitrogen to reduce the lithium loss rate in the process of manufacturing lithium battery electrode sheets. And due to the increase in demand for oxygen and the upgrading and optimization of oxygen production technologies, there have been big changes in the method of oxygen supply, and more and more enterprises are giving priority to VPSA and PSA oxygen production equipment to better meet the oxygen demand.

In this regard, PKU Pioneer has been also striving to expand the application fields and scenarios of VPSA and PSA oxygen generation technology. In October 2021, the company signed a cooperation agreement with CATL, a leading manufacturer in new energy batteries, to supply the client with a set of VPSA oxygen system. The product oxygen is designed to be used as the protective gas in the manufacturing process of lithium battery electrode sheets, which is the first time to equip VPSA oxygen plant to provide the protective gas in the lithium-ion battery industry in China. Using 93% enriched oxygen as the protective gas can fully meet the oxygen supply requirements of customers and lower the cost of oxygen consumption, which is of great exemplary importance for the application of VPSA and PSA oxygen generation technology in the battery area. So far, PKU Pioneer has further promoted the industrial application of VPSA and PSA oxygen unit in more than 20 segmented industrial fields to provide high-quality oxygen-rich solutions for customers in the iron & steel, non-ferrous smelting, papermaking, glass & glass fiber manufacturing, wastewater treatment, solid waste disposal and other industries, helping more than 300 users worldwide to achieve energy saving & cost reduction and overall improvement of economic efficiency.