Production Capacity

50Nm3/h-450Nm3/h, equivalent to liquid oxygen of about 1.7 TPD – 15.4 TPD.

Technology Brief

There has been a growing demand for small and medium-sized oxygen equipment with rapid development of the national economy in recent years. PKU PIONEER, seizing this market opportunity with its advanced technology and engineering experience of more than 300 sets of oxygen equipment, has produced the customized the new skid-mounted PSA oxygen equipment through its continuous development and innovation. The PSA-O2 generator meets a wide range of requirements for users in need of small and medium-sized oxygen equipment. It has remarkable advantages on its stability, simplicity, efficiency and energy saving.

PSA-O2 Generator Parameters (Oxygen Purity: 90%)

|

Model |

Oxygen yield |

Load adjustment

range |

Water Consumption |

Power Consumption |

Plot area |

|

ZO-50 |

50 Nm3/h |

50%~100% |

7 |

26 |

|

|

ZO-100 |

100 Nm3/h |

50%~100% |

12 |

39 |

|

|

ZO-150 |

150 Nm3/h |

50%~100% |

17 |

54 |

|

|

ZO-200 |

200 Nm3/h |

50%~100% |

21 |

65 |

|

|

ZO-250 |

250 Nm3/h |

50%~100% |

26 |

83 |

|

|

ZO-300 |

300 Nm3/h |

50%~100% |

28 |

83 |

|

|

ZO-320 |

320 Nm3/h |

50%~100% |

30 |

87 |

|

|

ZO-400 |

400 Nm3/h |

50%~100% |

40 |

109 |

|

|

ZO-450 |

450 Nm3/h |

50%~100% |

47 |

124 |

Note: The above data is based on the following design conditions: atmospheric pressure: 101.325 KPa; ambient temperature: 21 °C; relative humidity: 80%. The power consumption is converted into unit power consumption for 100% pure oxygen generation.

1. Advanced single-vessel process

Compared with the traditional double-vessel process, the world-leading single-vessel process

requires less equipment but brings more stable performance with easier operation and maintenance.

2. High efficiency lithium-based molecular sieve

The third generation of high-efficiency lithium-based oxygen generation molecular sieve (PU-8) has a

lithium ion exchange rate of over 99%, bringing plenty of advantages such as high strength, high

nitrogen and oxygen selectivity, large bulk density, uniform particles, long service life, etc. In

combination with the proprietary automatic filling technology, the stability of the molecular sieve

bed is effectively guaranteed.

3. Special valves for oxygen generation

Special valves for oxygen generation are more suitable for VPSA oxygen process, offering good

sealing, fast switching speed, stable performance and other characteristics, along with outstanding

low failure rate and easy maintenance.

4. Modular integrated design

Compared with the conventional double-vessel process, the equipment is more compact and the plot

area can be reduced by more than 20%.

5. Low operation cost

The power consumption of oxygen is as low as 0.29~0.32kWh/Nm3, the annual maintenance cost is 30% lower

than that of a common PSA oxygen generator. The annual comprehensive operation cost is also reduced

by more than 50%, compared with the cost of common PSA oxygen generator or purchasing liquid oxygen.

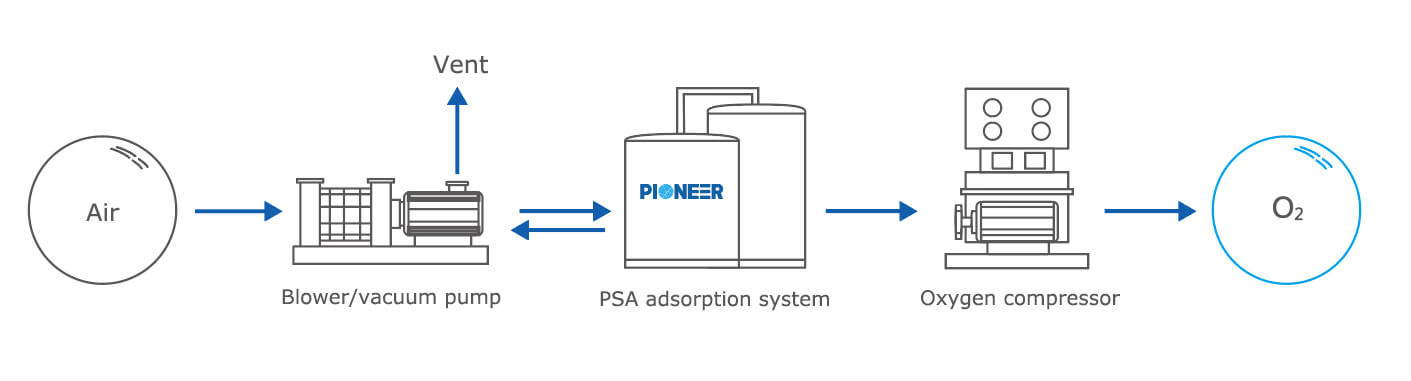

Adsorption process: the pressurized ambient air is passed through the adsorption vessel, where the impurity gases (i.e. predominantly nitrogen) are preferentially adsorbed by the molecular sieve. Oxygen is enriched at the top of the adsorption vessel, then enters an oxygen buffer tank to supply oxygen to the downstream;

Desorption process: after the molecular sieve is saturated by adsorption, the valve is switched to allow the blower to reverse act and vacuumize, thus restoring the adsorption capacity of the molecular sieve. In this stage, oxygen is continuously supplied to the downstream from the oxygen buffer tank.

Flow chart: